Woodville Toolroom

(By Darrell Thomas and Neil Pogson)

The Woodville Plant commenced in 1924, and by 1931 nearly 70% of the output of Holden Motor Body Builders was being used by GM (Aust). Bodies manufactured included, Cadillac, Buick, LaSalle, Oldsmobile, Pontiac, Chevrolet, and Vauxhall cars; and Oldsmobile and Bedford Light Trucks. HMBB became the largest vehicle body building business in the British Empire. It was during this period that the Woodville Toolroom began to emerge as a key resource for the Company.

GM [Australia] and HMBB decided to consolidate their interests and merged to become General Motor’s-Holden’s Ltd in 1931, and further expanded the Woodville site to more than triple its original size. The Woodville Plant was the head office of General Motor’s-Holden’s Ltd up until 1933, when it was decided to transfer this role to Victoria.

By 1935 there were 7000 people on the payroll of GM-H in Australia, with the Die and Fixture Department continuing to develop the Woodville Toolroom as a renowned facility for being able to take body blueprints and produce body tooling and construction methods unique for Australia.

Expert tradesmen, estimating personnel, die, fabrication & body engineering & process planners, equipment designers and draughtsman closely studied overseas designs, blueprints, illustrations and specifications to facilitate the evolution of the tools and equipment for the manufacture of vehicle panels and bodies. Every detail would be re-designed afresh for Australia, using ingenuity, innovation and established skills to transform designs to models, and reshape those models until the desired outcomes were achieved, knowing the equipment that was available to progress manufacture of the required dies, jigs and assembly fixtures.

The Woodville Toolroom demonstrated its significant technical and innovative skills during World War II, and was a major player in the manufacture of Australian defence needs. The GM-H organization supported the war effort, with mass production of anti-tank guns, aircraft sections, wing frames and fuel tanks, armoured military vehicles & truck bodies, marine craft, naval shells and

Torpedos, bridging pontoons, cordite presses, various bomb components, army work boots, and canvas goods, including haversacks and tents.

Following the war, the Woodville Toolroom and Die & Fixture Department was responsible for the majority of the development and tooling work for the first all-Australian car body system (the Holden 48-215). All the panels, panel assemblies and bodies, were manufactured at the Woodville plant. The Woodville Toolroom provided the necessary tooling for vehicle body production purposes, together with checking fixtures and gauges for quality control. This includes the dies for over 170 stamping presses, assembly fixtures for a variety of press welders and a multitude of other weld gun and specialised tools or machines as required for “on-the-line” body construction and assembly.

Social activities were also well catered for, with many sporting and cultural clubs being popular and well attended. There were the usual Football and Cricket Teams, but also a Camera Club and a Travel Club for instance.

In the 1960’s the Woodville Toolroom was reputed to be the largest facility of its type in the southern hemisphere. In its heyday, this plant produced the dies, jigs and fixtures for a new model Holden car every two to four years, with a ‘facelift’ every year. This was an enormous achievement when you consider the number of major components and the number of operations which make up each part in that new vehicle. The Woodville site also boasted the largest press shop and chrome plating plant in the southern hemisphere.

Sections within the Plant 5 Toolroom included Pattern Shop and Model Rooms, Lead, Aid & Template Sections, Detailing Groups, Small, Medium and Large Machine Shops, including state of the art ‘Keller Machines’. At the time, these large Kellers were the forerunners to CAD-CAM techniques, precision milling machines that exactly reproducd the required shape to a male or female die casting half, as traced from a model or precise plaster aid.

There were also Small, Medium, Large and Blank Die Manufacturing Sections supported by Die Try-out Sections (including appropriate try-out presses and welding equipment), Jig, Fixture & Weld Gun Shops, Die Maintenance, Pilot Room, Heat Treatment Section, Blacksmith Shop, Gauge Manufacture, Metrology and Checking Centres, and Apprentice Training Centre. There was also a foundry on the Woodville site, but for timing reasons, the casting of many dies was outsourced to local foundries.

Apprenticeships in the Woodville Toolroom commenced in 1934 and in those days the trades on offer were, Pattern & Motor Body Building, Motor Body Panelling, Motor Body Trimming, Motor Mechanics and Plumbing. A special Apprentice Training Centre was first established in the middle of the Toolroom in 1945, and generally between 50-60 new apprentices started each year, although in the late 1960’s the figures rose to around 100 before falling to low numbers in the 70’s and 80’s prior to the closure of the Woodville site in 1990.

HMBB produced the first bodies for the GM Export Company on the 29th November 1923, and exactly 25 years later to the day the famous Holden 48-215 was released in Australia in 1948. Significantly the Woodville Plant achieved its 50 year milestone in November 1973.

References:

| Date | Subject | Link |

| 1939 Mar 21 | Woodville Toolroom to supply jigs and fixtures to war effort | |

| 1943 | Toolroom view1 | JPG |

| 1943 | Toolroom view 2 | JPG |

| 1945 Jul 28 | Holdens Toolroom Basketball club | JPG |

| 1949 Sep | People Magazine, Toolroom Woodville feature | |

| 1949 | Woodville Apprentices | JPG |

| 1951 Oct 04 | Toolroom Travel Club go to Kangaroo Island by plane | |

| 1954 Jan 12 | Toolroom men wanted - typical advertisement | JPG |

| 1955 | Kellers precision Milling Machines | JPG |

| 1958 Mar 14 | Woodville and Birkenhead 25 year dinner program | |

| 1960 to 82 | Woodville photos | |

| 1960s to 70s | Woodville photos | |

| 1976 Feb | Facts and Figures | |

| 1977 Oct | Facts and Figures | |

| 1983 Dec | Existing usage of Plant 5 Major machines | JPG |

| 1983 Dec | Existing usage of Plant 5 | JPG |

| 1987 Aug 07 | Woodville Toolroom Staff | JPG |

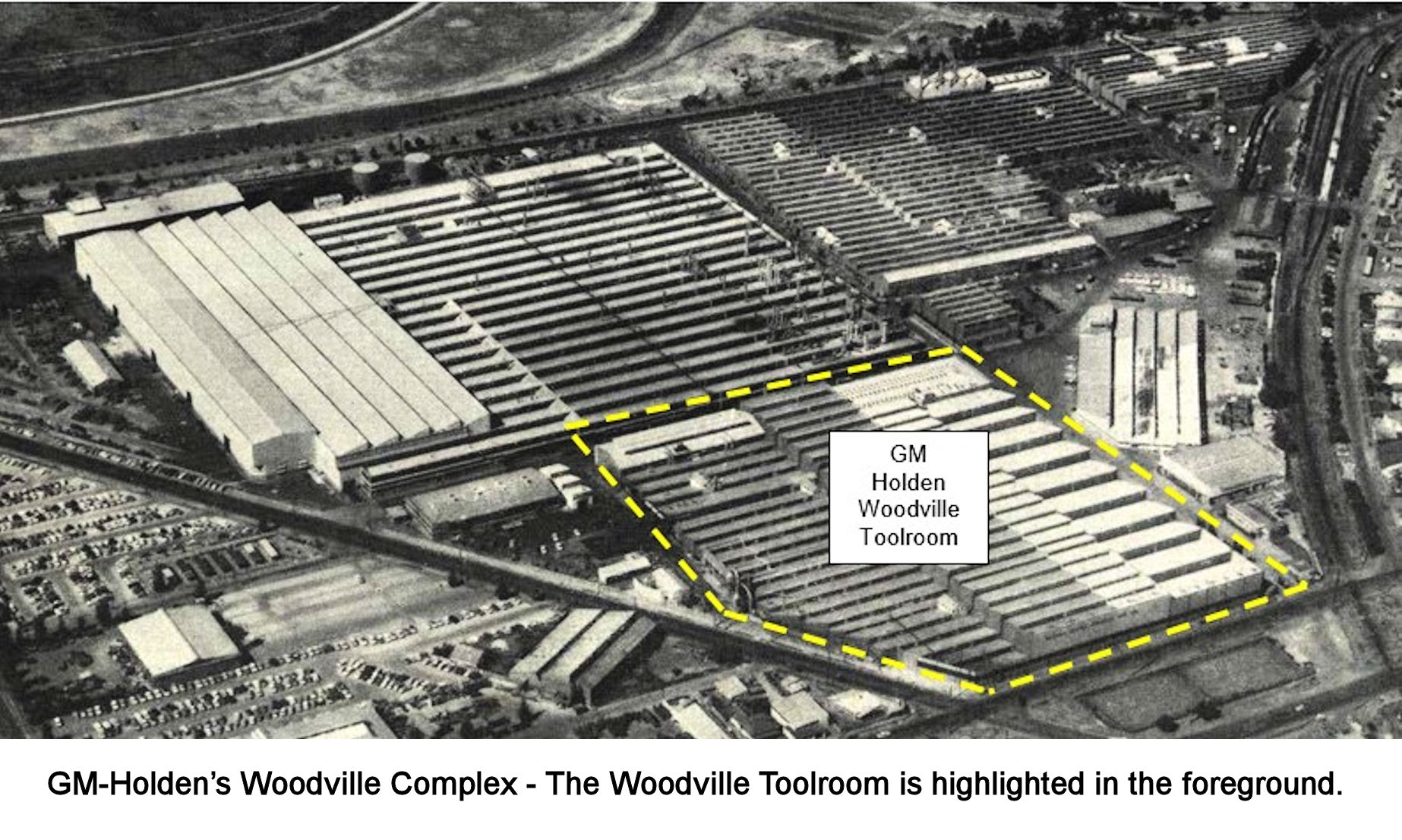

| Woodville aerial view, Toolroom location marked up | JPG | |

Memories of the Toolroom

In 2004, at the annual Toolroom 25 Year Club Dinner it was suggested that members should put their memories in writing so they should not get lost once the members passed on. Thirty two members responded (some more than once) and their accounts of the past doings of the Toolroom are recorded here.

| Contributor | Link |

| Bert Lincoln | |

| Bob Phillips | |

| Brian Barnes | |

| Colin Abraham | |

| Colin Brown | |

| Colin Golding 1 | |

| Colin Golding 2 | |

| Colin Wallis | |

| Dick Neville | |

| Don McDonald | |

| Don Sloper | |

| Ivan Rilling | |

| Jeff Francis | |

| Jim Jolley | |

| Jim Moffatt 1 | |

| Jim Moffatt 2 | |

| John Badcock | |

| John Langley | |

| Karl Koenig | |

| Karl Wilkinson | |

| Ken Ellis | |

| Kevin O'Keefe | |

| Len Harvey | |

| Malcolm Kageler | |

| Mel Murphy 1 | |

| Mel Murphy 2 | |

| Mel Murphy 3 | |

| Peter Collins | |

| Peter Gassner | |

| Peter McLay | |

| Sammy Hayes | |

| Stan Quilliam | |

| Tom Phillips | |

| Vince Tripodi | |

| Walter Scott |