Woodville Plant (Adelaide)

2: Building and Expansion.

(By Neil Pogson)

“HOLDEN'S NEED BIGGER WORKS.

LARGEST OWNED OUTSIDE CANADA.

ADELAIDE MOTOR BODY INDUSTRY

“To develop in a little more than five years from an unpretentious shop to the largest institution of its kind in the British Empire outside Canada sounds much like magic. There is, however, nothing in the nature of romance about the phenomena, expansion of Holden's Motor Body Builders, Limited.

…(T)he phenomenal demand for their products has made it necessary for the directors considerably to extend their Plant. With that object, 22 acres of land have been purchased at Woodville. Ten acres are being used for a building, which is being erected with a speed and thoroughness quite in keeping with the firm's business. The new plant and machinery, costing between £70,000 and £80,000, it is hoped, will be completed by November.

The recently secured contract for 60 tram cars from Melbourne, will be constructed at the new works. A railway siding and roads, costing between £2,000 and £3,000, is nearly completed. A spur set of rails runs right into the building. That means that practically the whole of the loading and un-loading will be done under cover. “

(Edited extract from Advertiser, Tuesday 2 October 1923).

As described elsewhere on the Land Acquisition pages, Holden Motor Body Builders bought land in Woodville in mid-1923 and immediately set about building factories to manufacture car bodies and Railway/Tramway carriages. The most pressing need was for a wood mill, as the requirements were already outstripping the capacity of the King William St facility, to the point that another factory had been leased at 12 Halifax St to allow the wood mill production to keep pace with demand.

The quantity of timber required was prodigious. The (smaller) King William St factory already used 2 Million feet of timber per year. Reports said that HMBB were chartering their own ships to ensure continuity of supply. The Schooner “Katherine” arrived in August 1923 carrying One Million feet of Maple, and a further One Million feet arrived on the Steamer “Nipsic” in December. The wood area at Woodville was sized to allow stacking of 4 Million feet of Maple, as it had to be seasoned before use.

The buildings went up quickly. In August 1923 HMBB announced that they had accepted Tenders for $40,000 to build the new factories.

The Adelaide News reported on 30 October 1923:

“The Woodville extension is proceeding with a merry swing. Some idea of the number of employees the plant will require can be gained from the fact that a special train will be necessary to convey them to Woodville in the morning and bring them back to the city at the conclusion of the day's work.

Arrangements have been finalised with the Railways Department to run a "special" into the works at 7.25 a.m., leaving again at 5.5 p.m.”

It is well documented elsewhere that General Motors, when setting up their General Motors [Australia] Pty Ltd operation had approached HMBB to be their sole supplier of bodies in Australia. The Holden Board agreed the contract with G.M. in December 1923, and although no capital was invested in Holdens by New York, HMBB were to receive advice of future planning and equipment selection and purchasing. This arrangement came into effect in 1924 when the Woodville Plant came into full operation.

In 1924, orders were received from General Motors [Australia] absorbing the full capacity of the new plant – 300 bodies per week, produced by 2,000 employees. Other makes continued to be made at King William St.

As demand continued to rise, the Directors considered that greater efficiency could be gained by moving everything out of King William Street and putting all the facilities under one roof at Woodville.

On 16 July 1926, announcement was made of further extensions will be made to the Woodville works of Holden's Motor Body Builders, Limited. “A contract has been let for extending the closed body plant, and another will shortly be let for the erection of additional buildings to house new woodworking and iron working machinery. When these are completed they will provide a further 200,000 sq. ft. of floor space on the western side of the works.

Mr. E. W. Holden, B.Sc. (Chairman of Directors) stated that the extensions to the works and the introduction of the new machinery were part of a programme for the re-organisation of the plant to increase the efficiency of the works. It was expected that the company would be turning out between 1,100 and 1,200 bodies a week from August.”

Mr E.W. Holden then announced in August 1926 that the machinery at King William Street would be dismantled and progressively moved and reinstalled at the Woodville Plant, It would be done gradually to prevent any disruption to production. Many office staff had already been relocated.

“Mr. E.W. Holden stated that by concentrating activities at Woodville a saving in transportation costs would be affected with a consequent cheaper cost of production. Extensive additions have been made to the Woodville works, which now occupied an area of 224,000 square feet. Estimated production for the current year was 25 per cent higher than last.

Up to date machinery had been purchased abroad, and to conform to the firm's policy of keeping abreast of the times, two foremen were now in America to gain the latest ideas in body building. Quality first was the maxim of the management.”

In the event, it took twelve months to complete the transfer.

Tenders were again called in June 1927 for “Extensive additions, including reinforced concrete work to Factory, Woodville”.

So in 1927, because of the capacity now available, it was found possible to close down both the plants over the Christmas and New Year holidays, and to concentrate upon completing the transfer of King William Street facilities to Woodville - a task of considerable dimensions. By the end of December, and excepting the timber mill, the transfer was concluded and the doors of the King William Street plant closed for the last time. By the end of January 1928, all operations would be carried out at Woodville.

The business pages carried a notice that “on and after the 9th January, 1928, the Registered Office of Holden’s Motor Body Builders will be situated at Woodville, South Australia, instead of King William Street, Adelaide.”

In March 1927, it was announced that “Woodville District Council has leased a block of land in the plantations on Port Road to Holden's Motor Body Builders Limited. The land is situated opposite the works of the company, and will be used as a parking area for the cars of employees. A fence is being erected round the area by the company.”

“Holden's Motor Body Builders Limited is reorganising its Woodville factory at a cost of more than £250,000. This announcement was made by Mr. E. W. Holden, B.Sc. (chairman of directors).

Mr. Holden stated that as a result of the trading last year it was decided to reorganise the plant at Woodville to give an output of 300 car bodies a day working one shift. He pointed out that during the last four of five months of last year the company was compelled to turn out 1,500 bodies a week, and that necessitated an overtime premium of £40,000 or £50,000. The men had to work on Saturdays and Sundays, and some departments were going for the whole 24 hours of the day which was extremely costly.

To overcome the difficulty the company was balancing its plant so that each department could handle its 300 bodies-a day and eliminate the overtime premium.

'The alterations consisted in the consolidation of the two woodworking plants into one large mill, the effect of which would be to economise in plant and supervision. The capacity of the metal working department was being trebled, and the reorganisation involved the installation of gantries and overhead electrical cranes with the object of handling heavy dies used in pressing the panels during construction and also carrying them into the press.

In addition the gantries would pass the raw steel into the guillotines and shearing machines where it would be cut to size. It would then carried to the press and after treatment would again be taken up by the gantries instead of being handled individually. The saving in time to be effected by the gantries alone would be a large item.

In the die making department new plant had been installed among which, was a Keller milling machine which was almost uncanny in its operation. The wooden shape was put up on the machine and was copied automatically in steel with a minimum of effort. That machine alone cost £15.000.

The spring plant had been extended to avoid having to work overtime, and the whole of the assembling had now been consolidated into one plant. To save the men having to handle heavy bodies from one place to another, chain conveyor lines were being erected and each body would be hooked on and conveyed through the plant, each successive operation being performed as the body passed the points.

Mr. Holden expressed the hope that the reorganisation would be completed by next

January.”

But in 1928 the volumes were only slightly up on 1927 (34,696 against 34,309), and with the economy going into recession leading to the Great Depression, began to fall significantly. At the lowest point, in 1931 only 1651 bodies were produced. All GMH assembly plants except Melbourne were shut down, and Woodville’s excess capacity was turned to making all manner of non-automotive items to keep some men employed. The return of increasing volumes was slow and it was 1934 before volumes passed 15,000 units in the year and eventually in 1938, reached 30,000 units.

World War II meant that all activities were turned over making War supplies, which is covered elsewhere in these pages. At the height of aircraft production, 2,000 men and women were employed as toolmakers and in production shops.

More than 75,000 special dies and jigs, ranging in size from a few square inches to 40 square feet were made. The designing of most of them called for new techniques because of the types of materials to be used, the comparatively small number of each part required, and the urgency of the work.

In 1941, a new building, Plant 10 was added to Woodville and paid for by the Australian Government. This was to allow the production of aircraft engine components. It was followed in 1943 by Plant 11, which was for the manufacture of components for the Polsten anti-aircraft gun.

More about the war activities at Woodville can be perused here.

With the War over, GMH turned to planning its recovery, and recommenced assembly of vehicles, plus gained agreement with the Australian Government, to Design, Engineer and sell a New Australian Car. Factory buildings were converted back to automotive use.

The Woodville Toolroom was heavily involved in the preparation for the manufacture of the car, designing and making Press Tools and many jigs and fixtures to aid the assembly operations. This is covered in another page.

In January, 1946, John Holden told the press “Developmental work in preparation for the manufacture of the Australian motor car, planned by the General Motors-Holden's organisation, is now under way at the company's big Woodville plant.

This is the first step in the undertaking, which, it is recognised, will make an important contribution to the industrial stability of the State.

The company's plans provide for a major share of the actual production of the GM-H car to be carried out at Woodville. They will also involve the allocation of additional work to a number of local sub-contractors, thus giving indirect employment to many more South Australian workmen.”

The new Holden car was an instant success and a waiting list soon grew as customers were prepared to wait literally for years for a chance to own one. Production volumes continued to outstrip projections and put pressure on the plants to increase their volumes. Woodville was no exception.

In 1948, Plant 11 was lengthened to match Plant 10, and also widened. Plant 10 became the Plating Shop, and Plant 11 converted to Trim Fabrication. But by 1954, they were incorporated into a much wider complex when a new Press Shop was built to house 72 presses (Plant 1). The old Press Shop was retained for Low volume and Custom work including use by the Toolroom for die tryout, allowing trials to be made without tying up the new high capacity presses. By now, the Plant occupied 61 acres.

The plant was now organised for body production: Plant 11 became the Body Assembly Shop, Plant 10 the Paint Shop and Plant 2 the Trim Shop (also housed Factory Stores).

In 1955 a further expansion, aimed at increasing vehicle production to 300 per day was embarked on. At Woodville, the Press shop (Plant 1) was extended to add 19 additional presses, the Body Assembly shop (Plant 11) was increased by 80,000 sq. ft. and now adjoined the Paint Shop (Plant 10) which was also increased by just on 50,000 sq. ft. This was achieved by extending all these Plant to the North as far as they could sensibly go.

This largely remained the layout at Woodville until the Elizabeth Assembly Plant construction got to a point where a staged transition of processing from Woodville could commence. Activities progressively transferred from Woodville to Elizabeth as each new plant started up at Elizabeth.

There was overlap but the transition broadly went as follows:-

- The Hardware Operation was the first to go in May through August 1959, along with the progressive transfer of Manufacturing Engineering and Admin functions.

- The Body Shop commenced production at Eliz in Feb 1962. These bodies were then road transported to Woodville for Paint and Trim Asm.

- All panels were still coming from Woodville to the Elizabeth Body Shop at this stage.

- Start of Production in the Paint Shop and Trim Asm at Elizabeth was in July 1963, with Trimmed Bodies being railed and road transported out to VAP’s.

- The Trim Fabrication (sewing, etc) move from Woodville to Elizabeth occurred with the Trim Fab building SOP at Elizabeth in January 1964.

- Metal Fabrication (sub-assemblies) were transitioned to Elizabeth in 1965.

- Full Vehicle Assembly started in Jan 1965 using a transition based on some Birkenhead HD Model vehicles being assembled at Elizabeth, along with Final Asm of low volume Chevrolets, Pontiacs, Bedfords and Vivas.

- This now meant that Elizabeth was able to handle the new HR model build in 1966 without Woodville assembly overlap so all Body related activity at Woodville ceased.

- The Press shop started operations at Eliz in 1965 but the Woodville Press shop stayed in operation for a long overlap period as new press lines progressively became operational at Elizabeth.

(Thanks to Jeff Jamison for these details)

As the gradual transfer to all body assembly operations being transferred to the new plant progressed, Woodville was once again repurposed as a Manufacturing Plant and Toolroom.

Of the major buildings, Plant 1 was retained as a Metal Stamping Plant, Plants 2 and 3 for Out of Productions Spares (OOPS), with a Wood Mill on Plant 3 upper floor as well. Out of production spare panels were a major business requiring large amounts of capacity, and the Elizabeth press shop strategy discouraged any OOPS being mixed up with current production. Elizabeth already had more die changes per press line than any other GM plant in the world making it one of the most flexible plants in the world, so including OOPS often pushed the plant beyond its capacity.

Hence OOPS panels were mostly made at Woodville with the Woodville Press Shop being taken over by A I Automotive.

Plant 5 became entirely Toolroom for Jig and Die manufacture, apart from an area occupied by the head office activities. Plant 10 remained a Plating Shop and also housed the laboratory. Plant 11 was for Trim Fabrication and Trim Assembly.

The Woodville site remained fairly much without further significant change until its sale in 1984, except for some internal rearrangements required to accommodate various model changes. The one exception was that in 1968, an Automatic Transmission facility was set up in part of Plant 11 to manufacture Trimatic automatic transmissions. The Plant was officially opened on 7th April 1970 by MD Alexander Rhea, although the transmissions had been fitted to six cylinder LC Torana models since October 1969. The Trimatic was available across the Holden range until it went out of production in 1987.

Fears that the Plant was to be closed caused great unrest amongst the workers, although there had been many leaks which the Company had denied, saying that no decision had been made. A stolen confidential GMH internal document pointed to a merger with Nissan or Toyota being considered, as well as some concerns as to whether an adequate Press facility could be setup at Elizabeth.

An April 27, 1983 meeting between unions, business and Government was not attended by GMH causing the Mayor of Woodville to say that action just supported fears about the future of the plant. The meeting decided that GMH must be made "patently aware" of the social costs of any further winding down of operations at Woodville, and it criticised the Federal Government's failure to give direction to the motor industry in the national interest.

In May, GM-H announced plans to cut its workforce at Woodville from 2,100 to 600 by 1986, as part of a staff reduction of 2,800 nationally.

Some industrial action was called for, but on 13 July 1983, Len Townsend, the Federal Secretary of the Vehicle Builders Union said the closure of the Woodville plant was invertible, and unions now should sit down to negotiate the best possible deal for the workers. He criticised other unions, particularly the Amalgamated Metal, Foundry, and Shipwrights Union for their campaign agai1nst the closure. He also said that at a meeting last week VBU shop stewards at Woodville had accepted the plant must close.

The Woodville Plant site was sold to Emanuel (No 5) Pty Ltd in June 1984 for a reported $10 million and the Transfer registered on 29 July 1984. However, on 29 June 1984, GMH had arranged a four year Lease of the Trimatic factory area to expire on 30 June 1988, which enabled them to continue production and the supply of spare parts for the aftermarket.

The Government had made clear its desire to develop the site as a manufacturing park, following a recommendation in a report from a working party and $70,000 consultant study. However, the Emanuel offer was a happy surprise to the State Government who did not expect a private developer to take on such a large project. But the concept was not new to Joe Emanuel who, about six years earlier had bought and redeveloped the old Phillips electronics plant in suburban Hendon and successfully operated it as a smaller version of the Woodville plan, with manufacturers and the South Australian Film Corporation among its lessees.

Holden had selected some of the Woodville equipment to be moved to Elizabeth, which occurred over time with the last small press relocated late in 1990. Single presses were moved from Woodville into the Elizabeth Tool room, one was for tryout and another was used as a Spotting press. Other equipment moved was two Keller large die machining centres, and three milling machines, one with a very long table, the other a highly accurate, tight tolerance machine.

In November, 1989, Bliss Corp Ltd announced they had taken "..over a panel press shop, paint shop and associated facilities at the 55 acre Woodville operation from January,1990. About 100 employees will be recruited, mostly from the existing facility. A long-term lease for the site is expected,-to be finalised in the next two weeks." Bliss Corp Ltd mainly produced Out of Production Spares.

The remaining presses were then operated by firstly Bliss Corp Ltd producing OOPS and later AiA producing some production parts as well.

However, Bliss were soon replaced when the Press Shop was acquired by Autodom, and operated by their subsiduary, Ai Automotive (AiA). AiA started out only making spares for Holden but later took on some Spares for Toyota and Ford as well.

By around 2002 AiA was making low volume OE pressings for Holden Crew Cabs, fabricating Crew Cab tubs and black phosphating rear cross members for Holden after they had been fabricated by us at Elizabeth. AiA also painted spare panels for corrosion protection. Several Holden retirees helped out AiA at Woodville during the stage when this OE work was being done. Interestingly, AiA pressed the last model Monaro specific panels including HSV’s unique panels.

This continued until 2012, when Autodom announced that they were seeking to go into voluntary liquidation, claiming a combination of low auto sales and overly agressive price reduction demands by GMH and Ford had led to them becoming unprofitable. The Victorian Government said the real reason was "reckless and disruptive industrial action" at the Dandenong Plant. By now, Autodom subsidiaries AiAutomotive and DAIR Industries had factories in Dandenong in Victoria and Woodville in Adelaide, and between them,supplied Instrument panel support beams, Seat frames and components, Steering column parts, Hinges (body & interior), Chassis & suspension components, Body panels & closures and Out of production spares.

This prompted an immediate scramble for parts - Holden had only enough parts for four days of operations, and Ford had enough for two days. They could be forced to shut production lines.

And it emerged that although Autodom directors had called in administrators on Monday, they were overtaken by secured creditors who on 6th November appointed receivers McGrathNichol to prepare the business for sale.

Negotions ensued, and on 7th November 2012 it was announced that GMH, Toyota and Ford had agreed to stand guarantor for Autodom's debts, so production resumed.

ooo000ooo

| Year/s | Date/Description | Link |

| 1923 | Woodville site before construction | JPG |

| 1923 | Summary - Evolution of Woodville 1923 to 1983 (Jeff Jamison) | |

| 1923 | Woodville site under construction | JPG |

| 1923 | Aug 25: New site at Woodville | JPG |

| 1923 | Aug 29: Tenders accepted for Woodville | JPG |

| 1923 | Sep 14: Woodville plant outlook | |

| 1923 | Sep 22: Australian Motor Body workmanship upheld | |

| 1923 | Oct 02: Holdens need bigger works | |

| 1923 | Oct 30: Progress at Woodville | |

| 1923 | Photos of Construction of new Plant | |

| 1923 | Woodville Plant layout | JPG |

| 1924 | Woodville Rail Tracks within the Plant | |

| 1926 | Jul 16: Holdens Woodville to expand | |

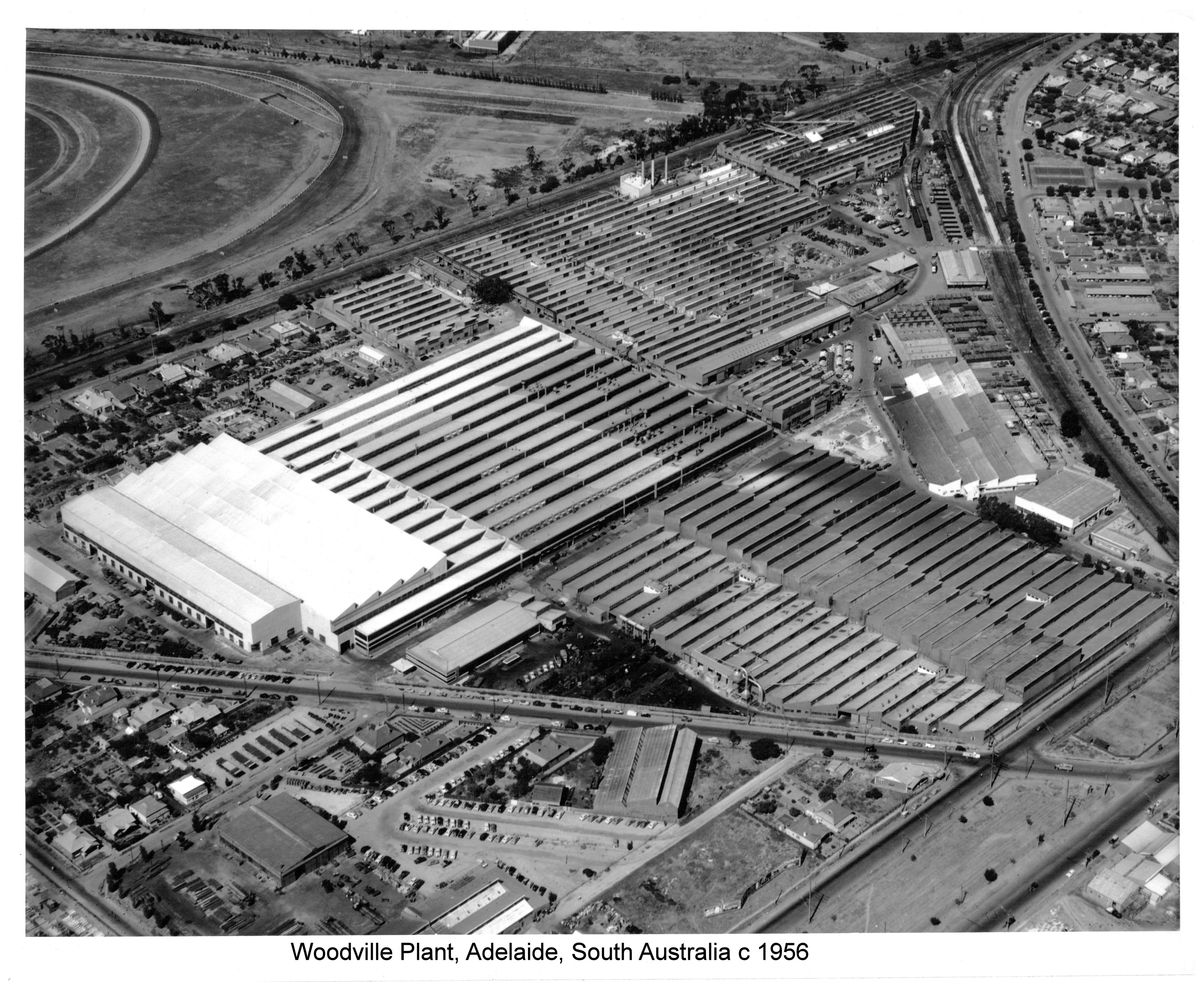

| Various | Five aerial views of Woodville Plant, 1926, 1932, 1946,1956, 1958 | |

| 1927 | Feb 28: Woodville causes problems for neighbours | JPG |

| 1927 | Mar 15: Car Park for Woodville employees | |

| 1927 | Jun 09: Tenders for extensions at Woodville | JPG |

| 1927 | Sep 02: Reorganisation of Woodville announced | |

| 1927 | Sep 03: Reorganisation of Woodville announced | |

| 1927 | Woodville Mgt Group outside offices | JPG |

| 1928 | HMBB Woodville Photos of activities to build bodies | |

| c1928 | Workers leaving Woodville Plant at the end of the day to board special train. Picture taken from Water Tower, | JPG |

| 1929 | Sep 21: threat to move from South Australia to Melbourne | |

| 1929 | A guide to Woodville with useful data | |

| 1930 | Jul 04: Putting South Australia on the map | JPG |

| 1932 | Dec 31: Outlook for 1933 to be better | JPG |

| c1935 | Four views of Woodville Press Shop, c1935 | |

| 1936 | Jul 30: Press_Shop_Photo | |

| 1937 | Sketch of Woodville Plant in 1937 | JPG |

| 1938 | Dec 17: Huge Expansion at GMH | |

| 1939 | Woodville Plant Aerial Photograph | JPG |

| 1940 | Jan 3: Fire in kiln at Woodville | |

| 1940 | Mar 12: Woodville Toggle press 350 Tons | |

| 1941 | Woodville workers going to Railway station at end of shift | JPG |

| 1943 | Small Press line | JPG |

| 1943 | Feb 1: View over Woodville Plant | JPG |

| 1943 | Hamilton Press | JPG |

| 1945 | Aug 18: SA Firms plan big expansion projects | |

| 1945 | Aug 13: Woodville Victory Anouncement | |

| 1945 | Aug 22: Cancellation of War Contracts | |

| 1945 | Dec 04: Factory Closedown due to electricity strike | |

| 1945 | Labour loading wall chart showing manning levels against WW2 activites. | |

| 1946 | Woodville Layout 1946 | JPG |

| 1946 | Jan 25 Aust Car Project in development at Woodville | |

| 1948 | Oct 2 GMH advertisement for staff at Woodville HMBB | |

| 1948 | Parts made in Woodville - A astonishing display of the number and variety of parts made at the Plant. | |

| 1951 | June: JR Holden and Thomas Playford at Woodville | JPG |

| 1952 | Woodville Construction photos | |

| 1953 | Woodville Construction photos | |

| 1954 | Aug 27 GMH Plans big expansion at Woodville picture | JPG |

| 1954 | Nov: Woodville Layout | JPG |

| 1955 | Woodville Construction Photos | |

| 1956 | Woodville Construction Photos | |

| 1957 | Woodville Construction Photos | |

| 1957 | Problems in establishing an Auto Manufacturing Plant in Australia - Lecture by F.P. Callahan | |

| 1957 | Cheltenham Pd. Woodville at shift change | JPG |

| 1958 | Woodville Construction photos | |

| 1958 | 9 Million Pound GMH Expansion | |

| 1959 | Woodville Construction Photos | |

| 1959 | Feb 06: Details of employee shift to Elizabeth | |

| 1959 | Woodvile tour brochure for NZ visitors | |

| 1960 | Woodville Expansion construction | |

| 1960 | Woodville Clearing Press foundation construction photos | |

| c1960 | Woodville Plant Aerial View | |

| 1961 | Woodville Expansion construction | |

| 1961 | Aug 10: AIM Visit to Woodville Tour brochure | |

| 1963 | Woodville Expansion construction | |

| 1969 | Apr 21: First Trimatic made at Woodville | JPG |

| c1969 | Woodville Trimatic Transmission Plant Brochure | JPG |

| 1972 | Mar: Woodville Layout | JPG |

| 1976 | Feb: Facts and Figures booklet | |

| 1977 | Oct: Facts and Figures booklet | |

| 1983 | Document prepared for the sale of Woodville site. | |

| 1989 | Nov 09: Bliss takes over Woodville Press and Paint shops | |

| c2012 | Woodville Press Line Auction Sale. | |

| 2012 | Nov 01: Autodom threatens to close | |

| 2012 | Nov 07: Workers jobs safe at Ai Automotive | |

| 2013 | Autodom Limited in liquidation |